Did you know that 96% of surveyed executives intend to initiate process improvement projects?

If you’re a leader/executive in a professional services business, you’ll understand the challenges of delivering remarkable user experiences and consistently driving growth. We believe proactive improvements are the way to live. By reducing busy work and efficiently providing service delivery, your business will break through traditional limits of productivity and client satisfaction to new heights.

This all-encompassing guide will explore the process improvement techniques that are most applicable in a professional services setting. Whatever your business strategy is, understanding and implementing these methodologies will empower you to transform your business operations.

Understanding Process Improvement

If you’re new to our blog, we’ll redefine Process Improvement. It is the systematic approach to analyzing and refining existing business processes for better outcomes. It’s about identifying bottlenecks, eliminating redundancies, and optimizing workflows to improve efficiency, productivity, and client satisfaction.

For professional services, process improvement is crucial. It enables firms to deliver consistent, high-quality services, manage resources effectively, and adapt to evolving client expectations.

Key Benefits of Process Improvement

- Increased Efficiency: Streamlined workflows and reduced waste.

- Improved Client Satisfaction: Enhanced service delivery and tailored experiences.

- Enhanced Profitability: Optimized resource allocation and increased revenue generation.

Key Benefits of Process Improvement

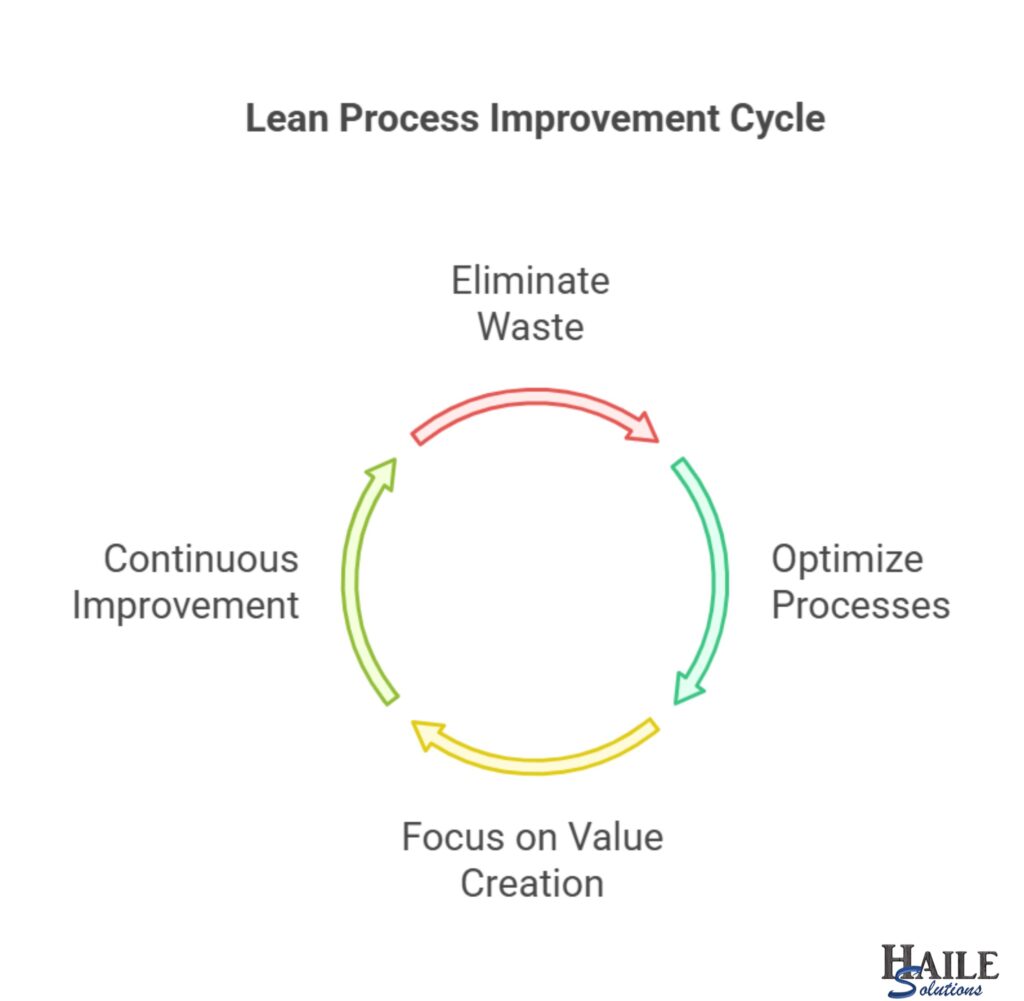

Lean

Lean methodology centers on waste elimination. Businesses can optimize resources and improve efficiency by identifying and removing non-value-added activities.

Six Sigma

Six Sigma is a data-driven methodology that aims to minimize process defects and variations. Businesses can identify improvement opportunities and achieve near-perfect quality by employing statistical analysis.

Lean Six Sigma

This hybrid approach combines Lean’s waste reduction focus with Six Sigma’s data-driven quality enhancement, offering a powerful framework for comprehensive process improvement.

Kaizen

Kaizen is a Japanese philosophy emphasizing continuous, incremental improvement. It encourages a culture where everyone identifies and implements small changes that lead to significant enhancements over time.

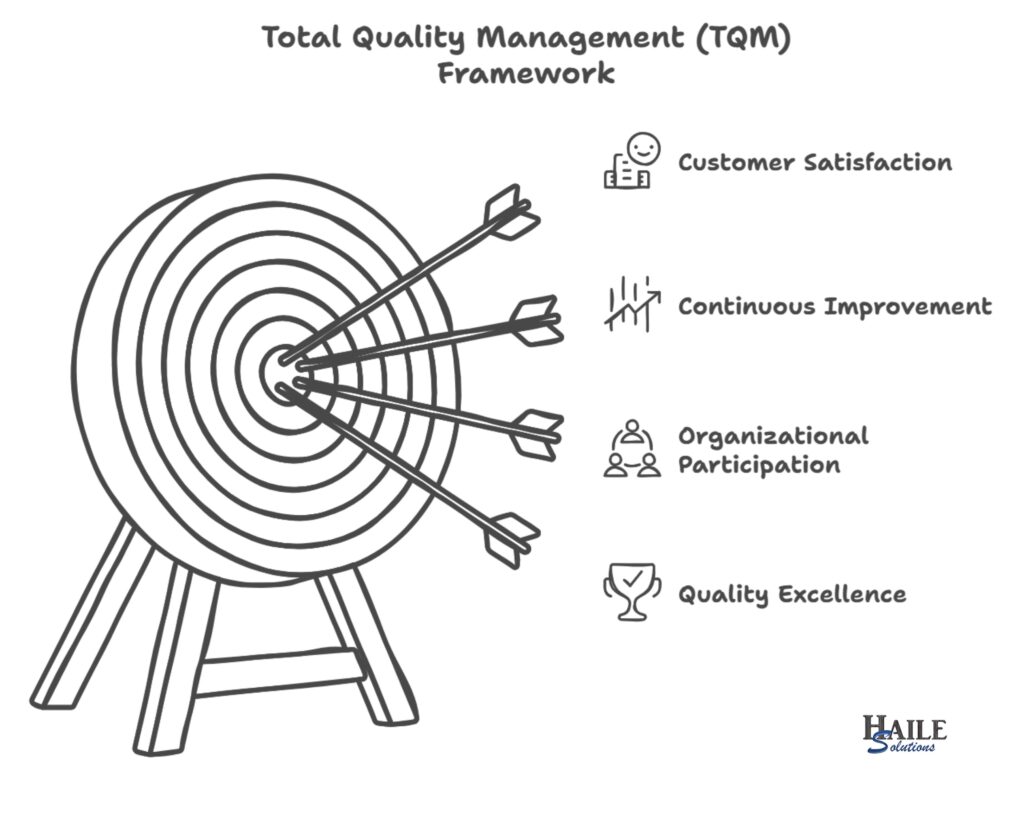

Total Quality Management (TQM)

TQM is a holistic approach that prioritizes customer satisfaction and continuous improvement. It involves every member of the organization in a relentless pursuit of quality and excellence.

Plan-Do-Check-Act (PDCA)

The PDCA cycle is an iterative, four-stage method for managing change. It involves planning, implementing, evaluating, and adjusting changes to ensure continuous improvement.

Theory of Constraints (TOC)

TOC focuses on identifying and addressing bottlenecks that hinder a system’s performance. By pinpointing and resolving constraints, businesses can optimize overall process flow.

Service-Specific Methodologies

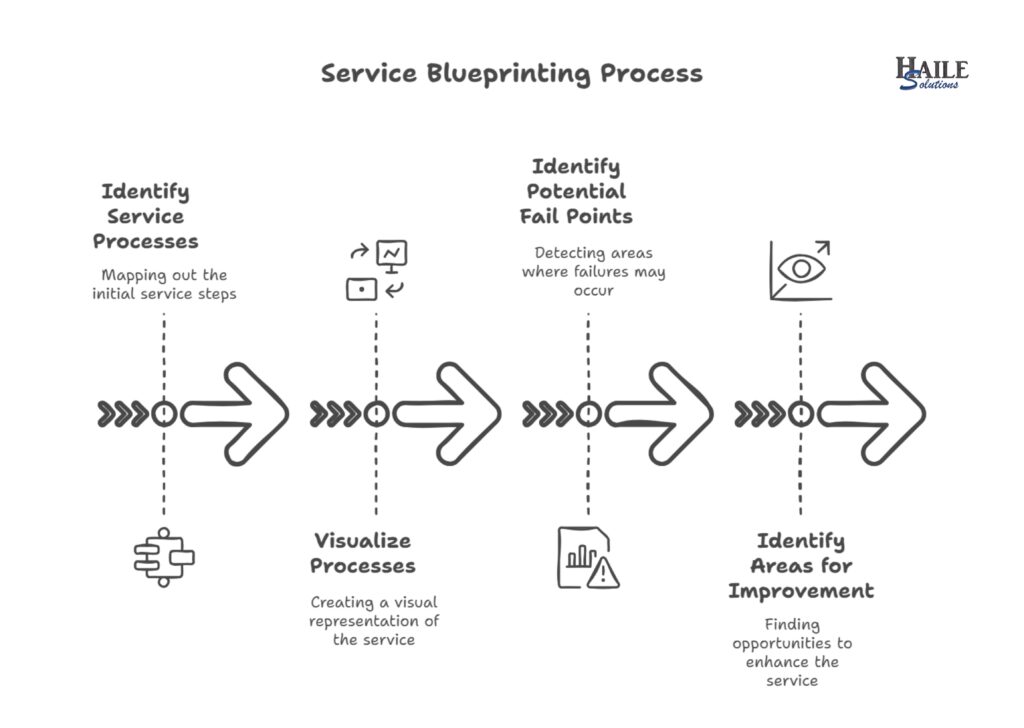

Service Blueprinting

Service blueprinting visually maps out service processes, allowing businesses to identify potential fail points and areas for improvement.

Customer Journey Mapping

Customer journey mapping visualizes the customer’s experience from initial contact to service delivery. This helps businesses understand customer needs and expectations, enabling them to improve service touchpoints.

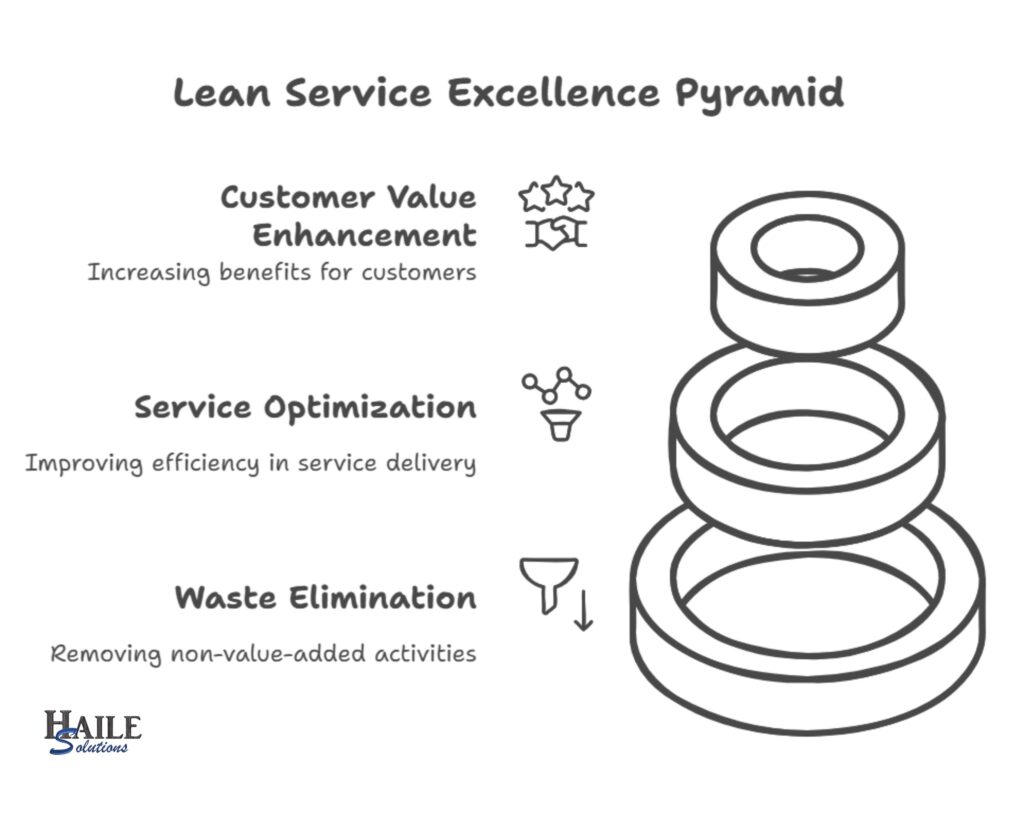

Lean Service

Lean service adapts Lean principles to service industries. It focuses on eliminating waste, optimizing service delivery, and enhancing customer value.

Additional Tools and Techniques

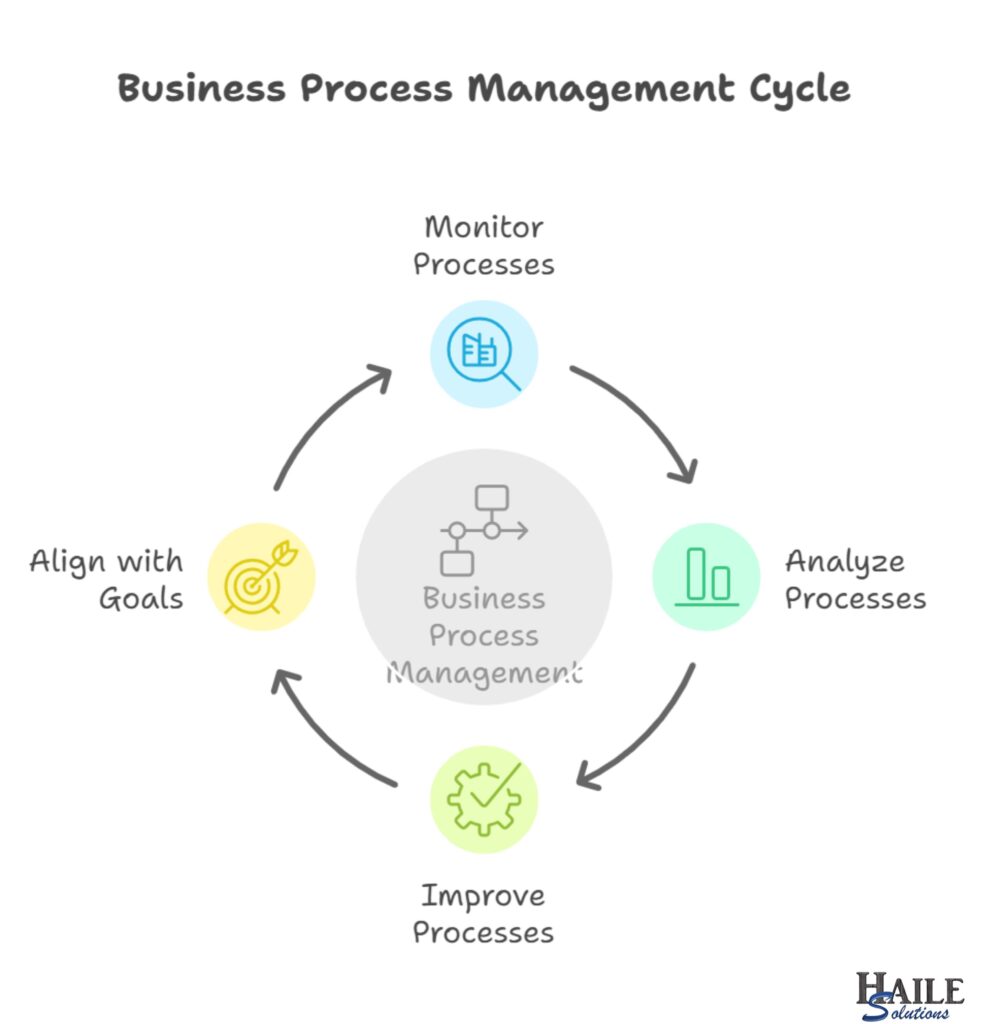

Business Process Management (BPM)

BPM is a structured approach to managing and optimizing business processes. It involves continuously monitoring, analyzing, and improving processes to align them with business goals.

Process Mapping

Process mapping visually represents workflows, allowing businesses to identify inefficiencies and areas for improvement.

Value Stream Analysis

Value stream analysis evaluates the flow of materials and information required to deliver a product or service. It helps identify waste and optimize the entire value-creation process.

Kanban

Kanban is a visual workflow management tool that helps teams visualize tasks and track progress. It promotes transparency and collaboration, enabling efficient workflow management.

5S

5S is a workplace organization methodology that creates a clean, organized, and efficient work environment. It involves five principles: Sort, Set in Order, Shine, Standardize, and Sustain.

SIPOC Analysis

SIPOC (Suppliers, Inputs, Process, Outputs, Customers) is a high-level process mapping tool that provides a comprehensive view of a process and its stakeholders.

Summary

Here’s a comprehensive comparison table of process improvement methodologies:

| Methodology | Focus | Key Benefits | Challenges | Best For |

| Lean | Eliminating waste | Increased efficiency, reduced costs | May overlook quality improvements | Streamlining workflows and reducing non-value-added tasks |

| Six Sigma | Reducing defects and variability | Data-driven insights, near-perfect quality | Requires expertise and resources | Improving quality in critical business processes |

| Lean Six Sigma | Efficiency + Quality | Comprehensive improvement framework | Resource-intensive, complex to implement | Large-scale process optimization |

| Kaizen | Continuous improvement | Builds a culture of improvement, engages employees | Incremental gains can take time | Establishing long-term improvements through small changes |

| Total Quality Management (TQM) | Customer satisfaction and continuous improvement | Organization-wide quality focus, improved client satisfaction | Requires full organizational commitment | Enhancing client satisfaction and service quality |

| Plan-Do-Check-Act (PDCA) | Iterative improvement process | Simple to understand, adaptable to many processes | Can be slow to show significant impact | Testing and refining process changes |

| Theory of Constraints (TOC) | Resolving bottlenecks | Clear focus on key issues, quick wins | Focuses on one constraint at a time | Optimizing resource-heavy processes with clear bottlenecks |

| Service Blueprinting | Visualizing service delivery processes | Identifies fail points, enhances customer experience | Time-intensive to create and analyze | Improving client interactions and service touchpoints |

| Customer Journey Mapping | Enhancing the client experience | Pinpoints client pain points, improves satisfaction | Limited to customer-facing processes | Optimizing the client lifecycle |

| Business Process Management (BPM) | Managing and optimizing workflows | Continuous monitoring, alignment with business goals | Requires robust technology tools | Long-term process governance and optimization |

| Process Mapping | Visual representation of workflows | Identifies inefficiencies, easy to implement | Limited to identifying problems, not solving them | Early-stage process improvement |

| Value Stream Analysis | Evaluating end-to-end process flows | Identifies waste, optimizes the entire value chain | Resource-intensive analysis | Improving cross-departmental processes |

| Kanban | Visual task management | Transparency, promotes collaboration | May not suit highly dynamic environments | Managing team workflows and task tracking |

| 5S | Workplace organization | Improved productivity, organized workspaces | Primarily focuses on physical environments | Setting up organized and efficient workspaces |

| Just-in-Time (JIT) | Reducing inventory waste | Cost savings, efficiency | Risk of delays or shortages | Reducing excess resources or inventory |

Choosing the Right Process Improvement Methodology

With such a long list of process improvement methodologies, it’s natural to feel a bit overwhelmed. But don’t let the options discourage you—this diversity is actually a strength. The key is to align your choice with your business objectives. Whether you’re focused on improving efficiency, enhancing client satisfaction, or driving profitability, there’s a methodology (or combination of methodologies) that can help you achieve your goals. And remember, you don’t have to go it alone—process improvement experts can guide you in adapting these tools specifically to your professional services business.

As an owner or VP of a small to medium-sized professional services firm, you face unique challenges. You’re not managing a factory assembly line; you’re running a business that depends on client relationships, skilled professionals, and efficient project delivery. The methodologies that work for a manufacturing company may not be a perfect fit, but many can be tailored to your needs with the right approach. Here’s how to choose the methodology that’s right for you.

Tip

For quick wins, start with simple tools like Process Mapping before moving to advanced methodologies like Lean Six Sigma.

Start with Your Objectives

Begin by clearly defining what you want to achieve. Are you trying to:

- Streamline internal workflows to reduce wasted time and effort?

- Enhance the client experience to boost satisfaction and retention?

- Identify and resolve bottlenecks in your processes?

- Improve profitability by optimizing resource utilization?

Understanding your primary goals will narrow your options and make it easier to focus on methodologies that align with your business needs.

Assess Your Current Processes

Before diving into improvement, evaluate the state of your existing processes:

- Encouraging employee involvement in identifying and solving problems.

- Regularly reviewing processes to ensure they remain aligned with your goals.

- Measuring progress through key performance indicators (KPIs) like efficiency gains, client satisfaction, and profitability.

Example

We recently worked with an advertising agency, and the processes were poorly documented. Sometimes, team members recorded videos, but the quality was variable. Their biggest pain point was that staff was overworked and overwhelmed to the extent they felt they were constantly reacting to situations rather than proactively adding value.

We worked with the CFO to review and document the processes using Process Mapping. Our decades of experience quickly identified missing processes, gaps in existing processes, and improvements. Our extensive technical knowledge helped them move from relying on many manual tasks and Excel to fully leveraging their ERP and automating many tasks.

As a result, the agency documented its processes, reduced hours wasted on manual repetitive tasks, reduced the potential for errors associated with exporting data to Excel, and saved hours of the staff time, allowing them to focus on adding value to the agency.

Final Thoughts

As the leader of a professional services firm, your focus is on delivering exceptional client experiences while managing resources effectively. Choosing the right process improvement methodology can transform your business operations and set you apart in a competitive market. Take the first steps toward sustainable growth and success by aligning your objectives, assessing your processes, and seeking the right expertise.

Remember, the perfect methodology isn’t about fitting into a mold—it’s about tailoring the tools to meet your unique needs. Start small, stay focused, and watch your business reach new levels of efficiency and profitability.

Ready to embark on your process improvement journey?

Check out our comprehensive resources, including our SOP library and templates. They’re designed to help you streamline your operations and achieve peak efficiency based on our founder’s 30 years of experience working in professional services businesses.

Process Improvement Methodologies FAQ

When selecting a process improvement methodology, you must consider your specific business goals, the maturity of your current processes, and the resources and expertise available within your organization. Aligning the methodology with your unique needs and objectives is key to successful implementation.

Organizations often encounter challenges such as resistance to change, lack of employee engagement, inadequate communication, and insufficient data analysis. Addressing these challenges proactively by fostering a culture of continuous improvement, providing comprehensive training, and ensuring effective communication channels can significantly increase the likelihood of success.

Process improvement initiatives can lead to increased employee satisfaction and retention by empowering employees to identify and implement process enhancements, fostering a sense of ownership and engagement. Streamlined workflows and reduced redundancies can also contribute to a more positive and productive work environment, further boosting employee morale and retention.

Emerging trends in process improvement for professional services include the adoption of intelligent automation, leveraging data analytics for process optimization, and incorporating design thinking principles to enhance customer-centricity. Staying abreast of these trends can enable organizations to remain competitive and deliver exceptional client experiences.

Organizations can measure the success of their process improvement initiatives by establishing clear metrics and tracking key performance indicators (KPIs) such as efficiency gains, cost reduction, customer satisfaction scores, and revenue growth. Regularly monitoring and analyzing these metrics allows organizations to assess the impact of their efforts and make data-driven adjustments as needed.

- Process maturity: Are your workflows well-defined, or do they vary from project to project? If they’re inconsistent, start with simpler tools like Process Mapping or Kaizen.

- Pain points: What are the biggest challenges your team faces? For example, if bottlenecks are slowing down client projects, the Theory of Constraints will be your best bet.

- Data availability: Do you have the metrics and insights needed to implement data-driven approaches like Six Sigma? If not, Lean or Service Blueprinting may be better starting points.